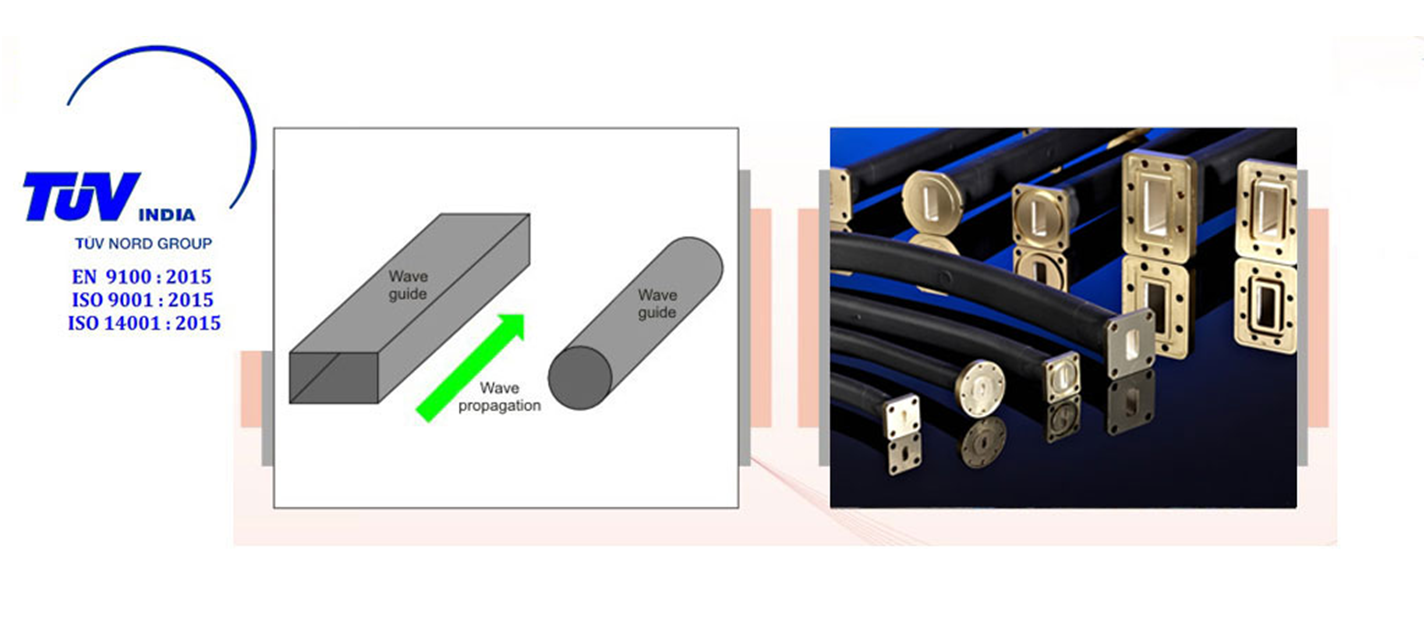

Rectangular Waveguide Alloy 6061

| Sr.No. | WG Type |

Frequency Range (GHz) |

|---|---|---|

| 1 | WR-340 | 2.20-3.30 |

| 2 | WR-229 | 3.30-4.90 |

| 3 | WR-187 | 3.95-5.85 |

| 4 | WR-159 | 4.90-7.05 |

| 5 | WR-137 | 5.85-8.20 |

| 6 | WR-90 | 8.20-12.4 |

| 7 | WR-75 | 10.0-15.0 |

| 8 | WR-62 | 12.4-18.0 |

| 9 | WR-51 | 15.0-22.0 |

| 10 | NS | 20.14-30.46 |

| 11 | WR-34 | 22.0-33.0 |

| 12 | WR-28 | 26.5-40.0 |

| 13 | WR-430 | 1.70-2.60 |

*Or as per Customer's required alloy and Specifications.

Round Waveguide Alloy 6061

| Sr.No. | Frequency (GHz) |

|---|---|

| 1 | 13 |

| 2 | 15 |

| 3 | 18 |

| 4 | 23 |

| 5 | 26 |

*Or as per Customer's required alloy and Specifications.

| Alloy | Standards Followed |

|---|---|

| Normally 6061 alloy is used. | IEC – 153 |

| Can be supplied in other alloy as per customer specification. | JSS 53000 |

| Siddhi have developed drawn tubes in 21 different alloys. | IS 4993 |

Advantage & Features

High Power Handling

Capacity

Low Insertion Loss

Very close Dimensional

Tolerances :- +/- 0.1 mm

Very Good surface finish :–

Ra 0.4 µ

Added Mechanical / Physical

Properties

Accurate Straightness :–

1:1500 mm

Very small (from 1 mm

diameter) very thin (from 0.2 mm) section is possible

Non-heat treatable, alloy

can be given in work Hardened Condition. Which results in added mechanical properties

Very precise Quality and

Eccentricity

Product Quality supported

by own state-of-the-art Quality Assurance Laboratory having all modern testing equipment

Special process like

precision cutting in small pieces (Tolerance of ± 0.2 mm)

Bending, Flaring, Punching,

Hard Anodizing and color Anodizing can also be carried out on request

Applications

These extruded and drawn products fulfill the requirements of Good Surface Finish; have

very close dimensional tolerances and added mechanical properties which are used

for:

Simply as a transmission

line

Rectangular and Circular

waveguides are commonly used to connect feeds of parabolic dishes to their electronics,

either low-noise receivers or power amplifier/transmitters

Communication and Radar

Microwave Oven

In scientific instruments

to measure optical, acoustic and elastic properties of materials and objects