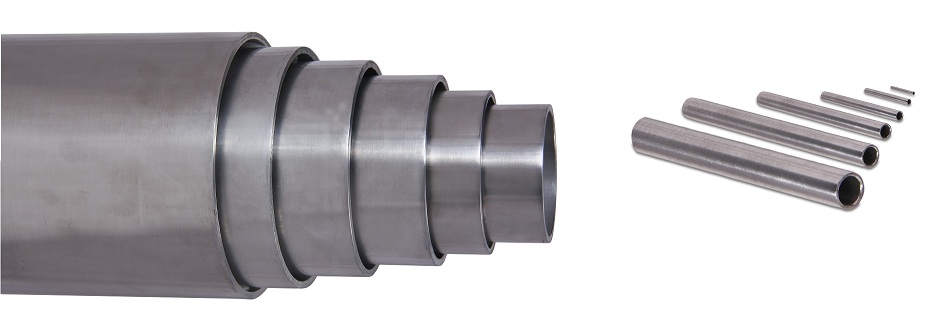

Telescopic Tubes Alloy 6061, 6082, 6351

| Sr.No. | Outer Diameter | Inner Diameter | Thickness |

|---|---|---|---|

| 1 | 28 | 25 | 1.5 |

| 2 | 24 | 21 | 1.5 |

| 3 | 12.70 | 11.30 | 0.70 |

| 4 | 15.90 | 14.5 | 0.70 |

| 5 | 19 | 7.60 | 0.70 |

| 6 | 22.2 | 20.8 | 0.70 |

| 7 | 25.4 | 24 | 0.70 |

| 8 | 63.50 | 60.26 | 1.62 |

| 9 | 57.15 | 53.91 | 1.62 |

| 10 | 50.80 | 47.56 | 1.62 |

| 11 | 44.45 | 41.21 | 1.62 |

| 12 | 38.10 | 34.86/td> | 1.62 |

| 13 | 31.75 | 28.51 | 1.62 |

| 14 | 69.85 | 66.61 | 1.62 |

| 15 | 76.20 | 72.96 | 1.62 |

| 16 | 50.80 | 44.50 | 3.15 |

| 17 | 51 | 44.45 | 3.275 |

| 18 | 55 | 48 | 3.5 |

| 19 | 63.50 | 57.20 | 3.15 |

| 20 | 76.20 | 69.90 | 3.15 |

| 21 | 88.90 | 82.60 | 3.15 |

| 22 | 101.60 | 94.50 | 3.55 |

| 23 | 114.30 | 107.20 | 3.55 |

| 24 | 127 | 119.90 | 3.55 |

| 25 | 115 | 107.80 | 3.6 |

| 26 | 102 | 94.80 | 3.6 |

| 27 | 89 | 81.80 | 3.6 |

| 28 | 76 | 69 | 3.5 |

| 29 | 10 | 8 | 1 |

| 30 | 13 | 11 | 1 |

| 31 | 16 | 14 | 1 |

| 32 | 19 | 17 | 1 |

| 33 | 22 | 20 | 1 |

| 34 | 25 | 23 | 1 |

*Other sizes can also be supplied as per Customer Specifications.

Advantages & Features

Very close Dimensional

Tolerances :- +/- 0.02 mm.

Very Good surface finish :– Ra

0.4 µ.

Added Mechanical / Physical

Properties.

Accurate Straightness :– 1:4000

mm.

Very small (from 1 mm diameter)

very thin (from 0.2 mm) section is possible.

Non-heat treatable, alloy can

be given in work Hardened Condition. Which results in added mechanical properties.

Very precise Quality and

Eccentricity.

Product Quality supported by

own state-of-the-art Quality Assurance Laboratory having all modern testing equipment.

Special process like precision

cutting in small pieces (Tolerance of ± 0.2 mm).

Hard Anodizing and color

Anodizing can also be carried out on request.

Telescopic Tube Applications

Military Telescopic Masts for

Ground Communication

Electro-Mechanical Mast

Pneumatic

Mast

Telecommunication Mast and

Antenna Mast